Bio-based materials

Did you know we were the first to introduce bio-based woven vinyl flooring? The top layer of our Strata, Palma, Alhambra and Hybrid collections contains ca. 40% bio-based content, replacing virgin fossil-based carbon with renewable plant-based carbon.

Bio-based carbon is derived from materials of biological origin, such as plant waste. The use of bio-based products leads to a reduction in CO2 emissions, toxic waste, and energy and water consumption during production processes.

We are proud to say we achieved the prestigious TÜV OK Biobased certificate for this innovation.

Recycled

PET content

We incorporate recycled content into our products: the acoustic backing – SonoFeltTM – consists of 70% recycled PET. For every 1000 m2 of 2TEC2 flooring, we save the equivalent of 15.000 PET bottles from landfill.

100%

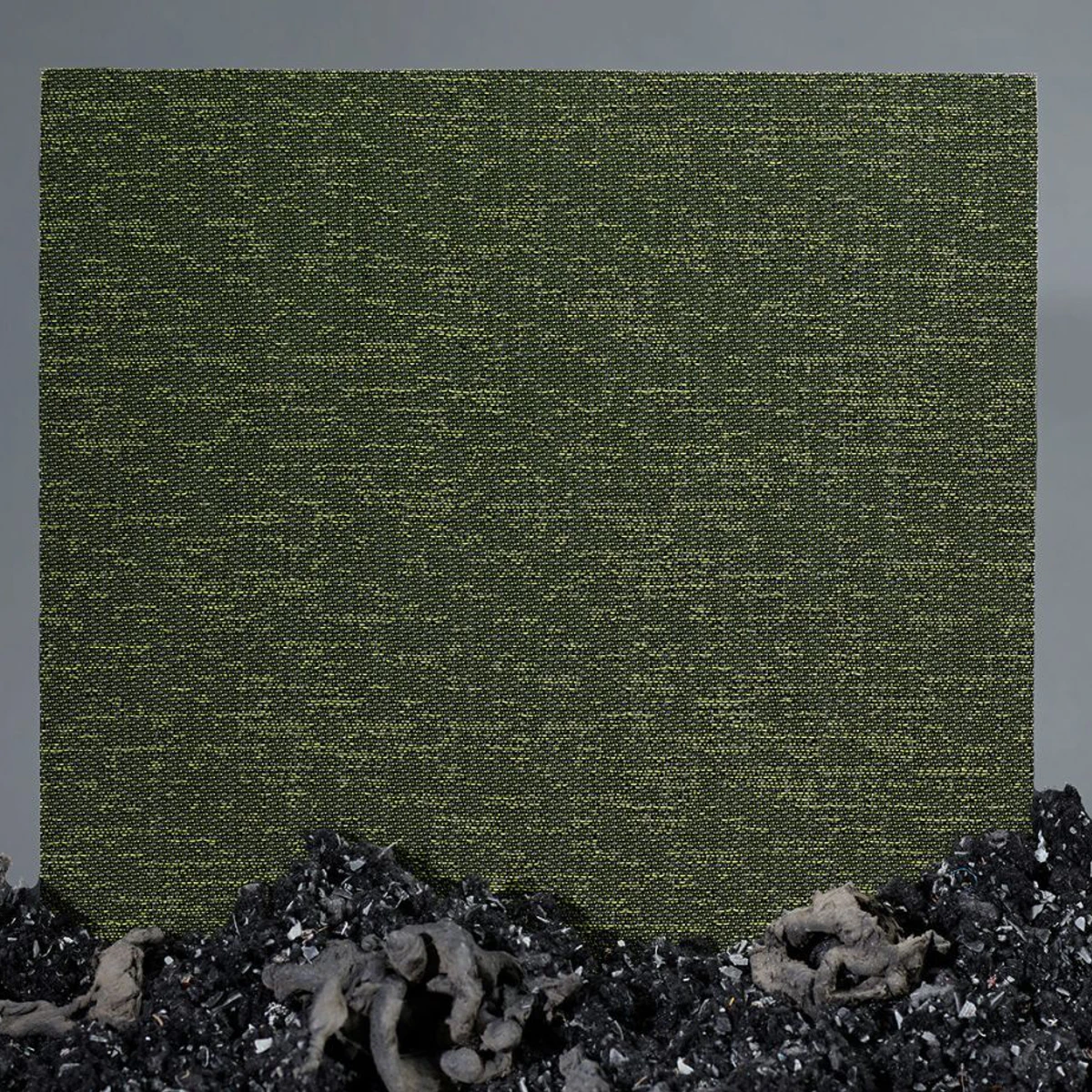

recyclable

2TEC2 is designed and produced to be recycled and to regenerate new 2TEC2 flooring again and again, without losing strength. After all, all materials introduced in our circular production cycle are meticulously quality-checked for composition and performance.

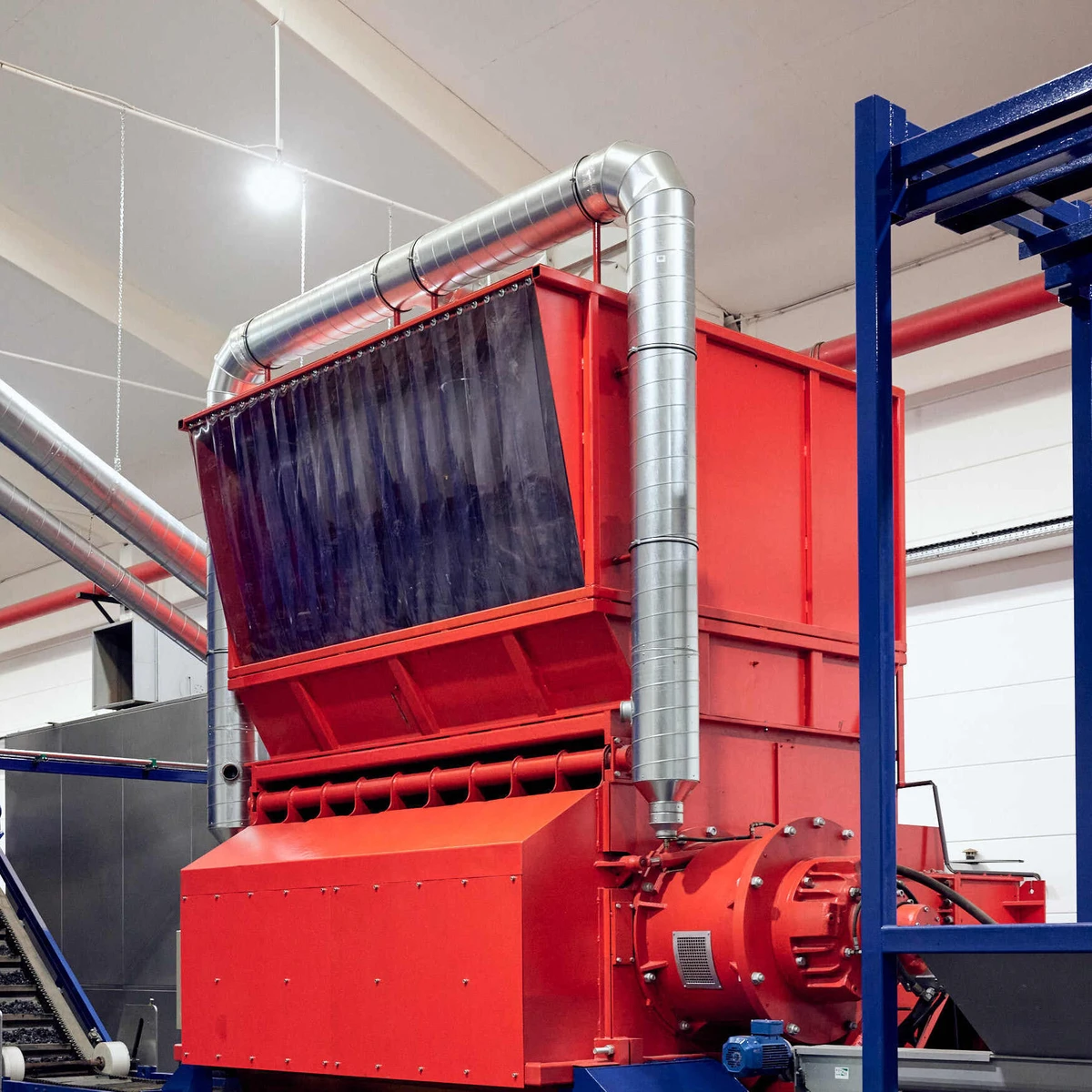

Recycling plant

Just a few kilometers from our production site, our new in-house recycling facility converts production waste into material of which new, strong and attractive tiles can be made. There is no change on the visual aspect, stability, performance, durability or other features of the recycled flooring.