What started as a small Belgian workplace specialising in stylish floor coverings is now a company that elevates the global market for woven vinyl floors to a higher level. 2TEC2 designs and produces beautiful yet eco-conscious floors for buildings and spaces where people spend up to 80% of their lives. “ ‘We care for your health, safety, and well-being’ is not just a slogan. It’s deeply ingrained in our DNA,” says CEO Philippe Hanet.

The Belgian press went in search of companies actively contributing to the transition to a carbon-neutral economy. 2TEC2 is the first company in the series. Read the original articles in Dutch or French here: De Standaard & De Tijd (Dutch), L’Echo & Le Soir (French).

2TEC2 is a 100% Belgian family-owned company that designs and produces high-tech floors. The brand focuses on weaving aesthetically refined tiles and rolls for the project market, aiming for superior performance in terms of quality, functionality, and innovation. The flooring is designed and produced from the outset with recycling in mind, to create new 2TEC2 flooring time and time again – without loss of strength.

Innovation-Driven Family Business

Innovation is at the core of 2TEC2’s approach, focusing on more than just improving aesthetics, acoustics, and practical usability. Their engineers and management are also passionate about environmentally conscious business practices, which is an essential part of their corporate philosophy. “We find incredible satisfaction in seeking solutions to complex problems and achieving technical feats,” Philippe Hanet smiles. “And often, that is tied to sustainability, where much progress can be made. Product lifespan is an important aspect.“

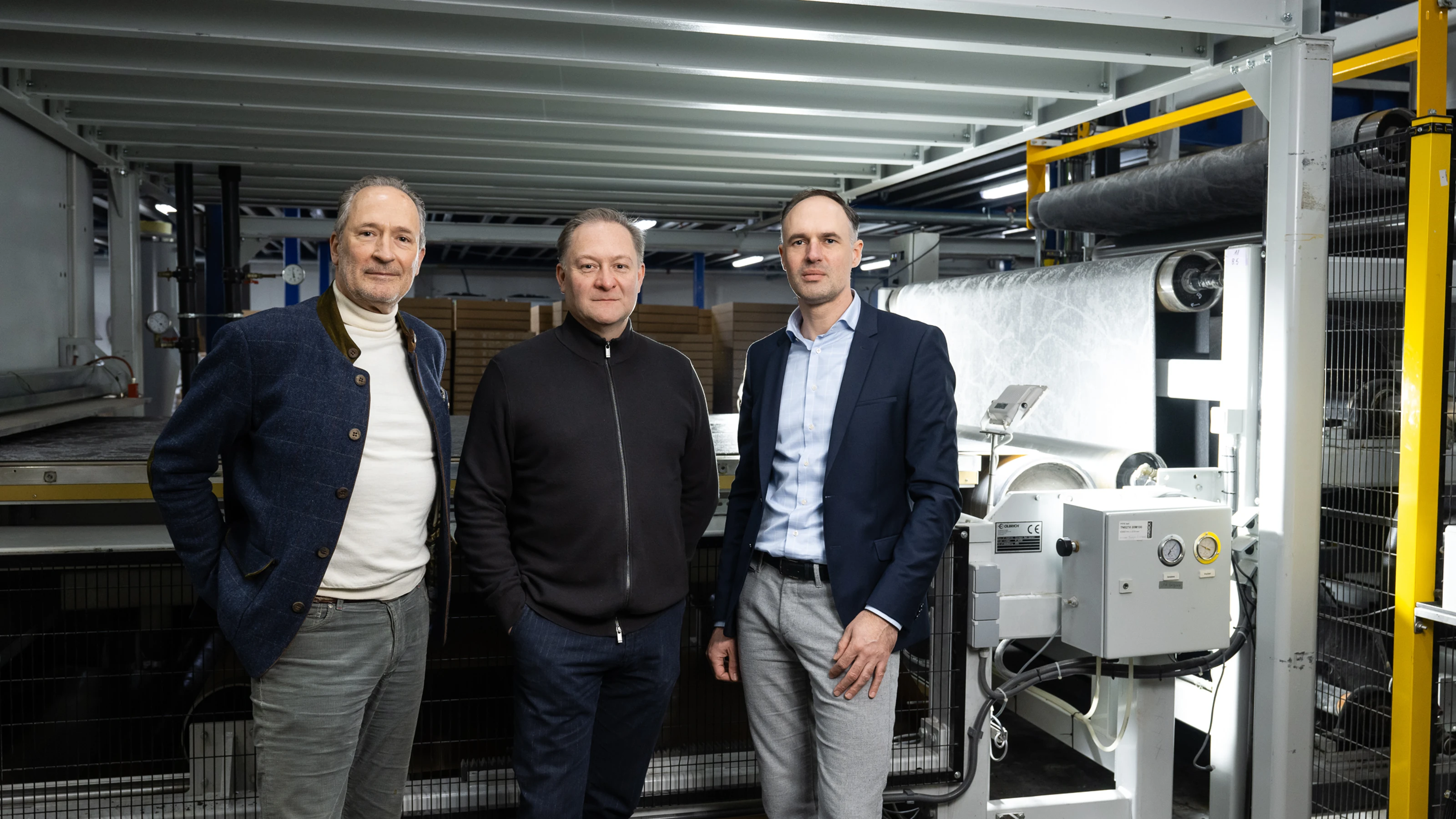

The identity of 2TEC2 as a family business, led by spouses Philippe Hanet and Katia Dewitte, founded together with brother James Dewitte, plays a role in this story. “Unlike publicly traded companies, we don’t just focus on short-term returns,” Hanet knows. “If it weren’t for this, we could never have achieved so much, as this has short to medium-term implications for financial results.”

SDGs as a Compass

To smoothly implement their sustainability strategy and achieve their goals, 2TEC2 established a multidisciplinary sustainability working group. Each quarter, top management evaluates improvements in corporate social responsibility and carefully plans necessary initiatives, including budget and resources. The compass they use for these decisions consists of 6 of the 17 Sustainable Development Goals (SDGs) of the United Nations. “This choice was not made lightly,” says marketing responsible Ingrid Macours. “As a management team, we debated this thoroughly. For instance, goal 11 ‘Sustainable Cities and Communities’ sharpened 2TEC2’s mission. Our ambition is to produce more sustainable floors, so that we can build and live more environmentally consciously.”

Plant-Based Materials

For the high-tech flooring producer, finding renewable raw materials was the primary challenge. “Last year, we collaborated with our raw material supplier on the development of bio-based pellets,” production director Thomas Vantieghem explains. “This allowed us to launch our first collection where the top layer of woven vinyl largely replaces fossil-based carbon with material of plant origin. This is a completely renewable source instead of newly extracted fossil carbon.” This search took some time because the product had to maintain its appearance, strength, environmental friendliness, or other properties. “We are truly a pioneer in product composition. This is also why this collection was nominated for the Inovyn award in the category ‘Value to Society: innovation and design’,” Hanet smiles.

The Challenge of Permits

Sustainability of production facilities was also an important focus. Thus, all production activities were integrated into one factory to avoid transportation to and from suppliers of raw materials or semi-finished materials. Additionally, 2TEC2 invested in 3,154 photovoltaic panels on the buildings and a large battery energy storage system (BESS), built on their own premises. Finally, they built an optimised closed-loop energy reuse system with a heat recovery system and closed water cooling system.

However, obtaining all permits from various government agencies and other parties proved to be quite challenging. “All stakeholders are not always well-aligned and have little experience with these new battery technologies, which greatly hinders our ecological ambitions,” Hanet explains.

Circularity

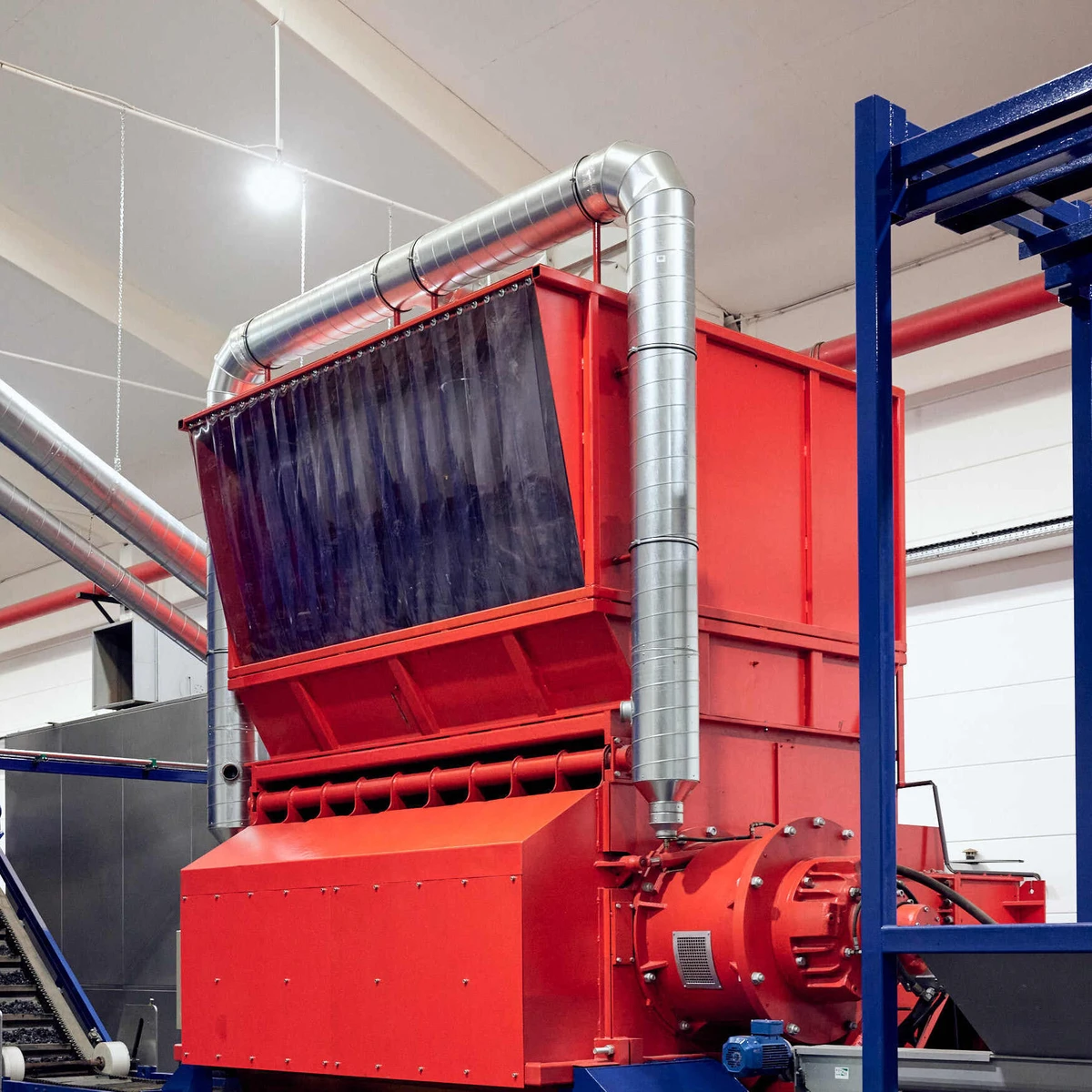

A third element in 2TEC2’s transition was the search for and analysis of complete recyclability. “We went very far in this,” Hanet says. “We conceived and built our own new recycling factory. A project that took nearly 5 years. However, this recycling factory offers fantastic opportunities, both in terms of business and environmentally conscious business practices, to even recycle materials from sector peers or even other industries, as long as it is the same pure and clean basic material as we use at 2TEC2.” “Ultimately, we want to use 0% virgin fossil-origin raw materials for our product composition and fully recycle and reuse our products ourselves,” adds Vantieghem.

Trusted Relationship with Banker

Of course, all these investments come with a hefty price tag. “The investment in time, research, and financial resources was enormous and suffered a 1.5‑year delay. This made it not easy for our financial partner,” Hanet acknowledges. “But BNP Paribas Fortis has been very flexible and collaborative in this. Our contacts at the bank and their directors were very involved. This partnership was crucial for us to take these steps financially.”

What Does the Future Hold?

There is no other option but to operate more consciously, 2TEC2 is convinced of that. “Previously, our production process ended with the delivery of the product. Now we go further to take it back and recycle it so that the loop is closed nicely. We are now in the phase where it is essential for products to have a second life after use by the consumer. Legally, there will be more and more obligations,” Hanet knows, “and architects and large firms are setting labels and certificates as a benchmark in choosing suppliers and products. So, it is essential to actively invest in this. The sector is already responding to all these changes. But we will have to do it together; one company cannot bear this alone. That’s why the participation of other companies, the government, and other players in the sector is necessary. To contribute to this, we are an active member of ECRA, the European Carpet and Rug Association.”